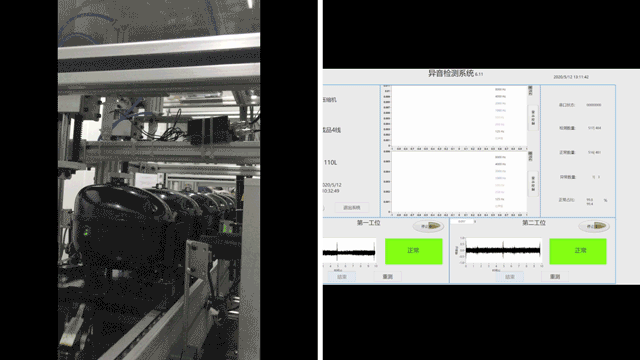

The Fully Automatic Online Intelligent Abnormal Sound Detection System for Refrigerator Compressors has been successfully applied in a professional domestic refrigerator compressor manufacturing enterprise and has passed the enterprise's final acceptance. The performance indicators of the system are as follows:

Detection Object: Refrigerator compressors

Detection Mode: Unmanned, fully automatic, real-time detection, no soundproof room required

Daily Detection Capacity: 7,000 units (at peak production)

Detection Signal: Vibration acceleration

Detection Cycle: 8 seconds per unit (including 5 seconds of judgment time)

Accuracy Rate: Over 99% for normal compressors; 100% for compressors with known faults

The following is an introduction to the Intelligent Abnormal Sound Detection System for Refrigerator Compressors from four aspects: principle, implementation steps, system composition and auxiliary functions.

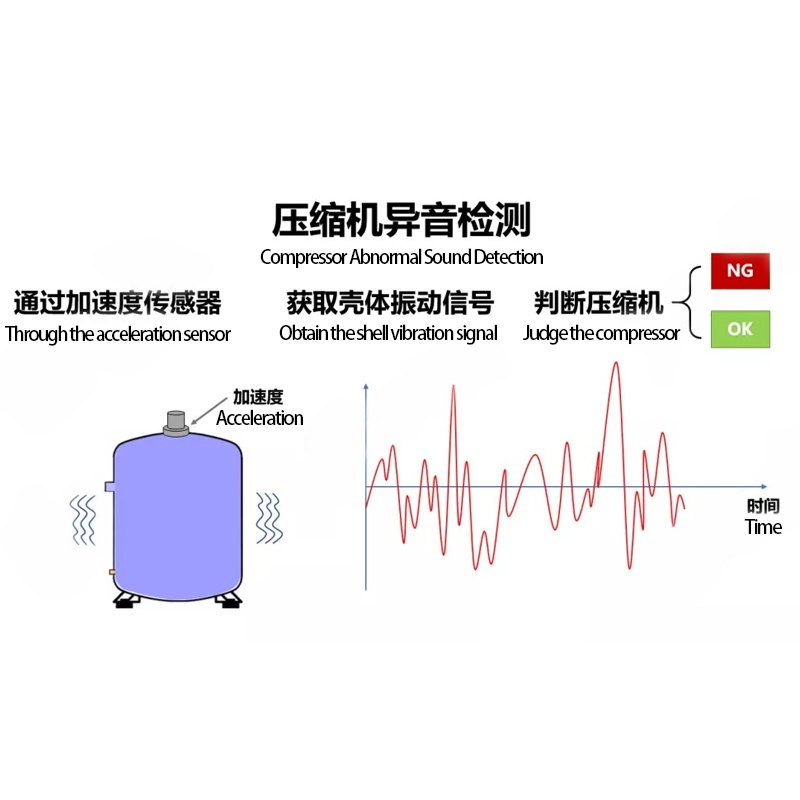

Since the operating sound of the compressor itself is very low, and the environmental noise in the production workshop is relatively high, it is not feasible to conduct abnormal sound detection through the compressor's acoustic signal. Therefore, for the abnormal sound detection of the compressor, an acceleration sensor is used to obtain the shell vibration signal, and then the vibration signal is used to determine whether the compressor contains abnormal sounds.

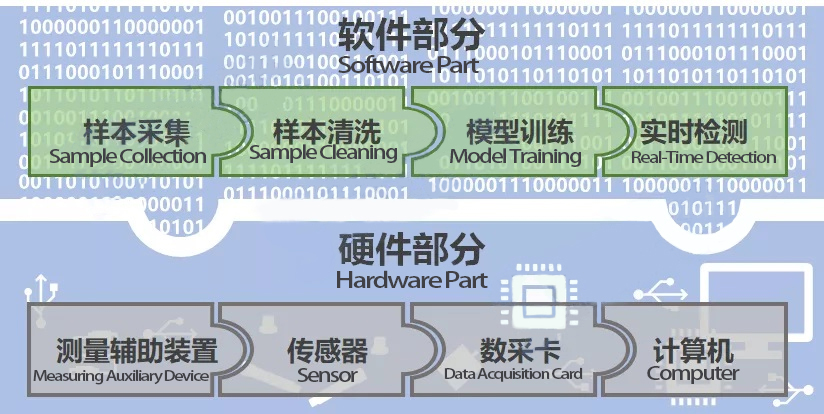

The implementation of artificial intelligence (AI) abnormal sound detection for compressors requires the completion of the following three phases in sequence:

Sample Collection: Vibration signal samples of the compressor are obtained through an acceleration sensor and a signal acquisition card. After data cleaning to remove samples that do not meet requirements, the remaining samples are used as the dataset for machine learning.

Machine Learning: An appropriate machine learning model is selected and trained on the dataset to obtain the parameters of the abnormal sound detection model. The model is then tested, and its parameters are adjusted until the test results meet the requirements.

Real-Time Detection: The abnormal sound detection model is deployed to the production line. Real-time collected signal samples are input into the detection model, and judgment results are obtained within one production line cycle to complete online real-time detection.

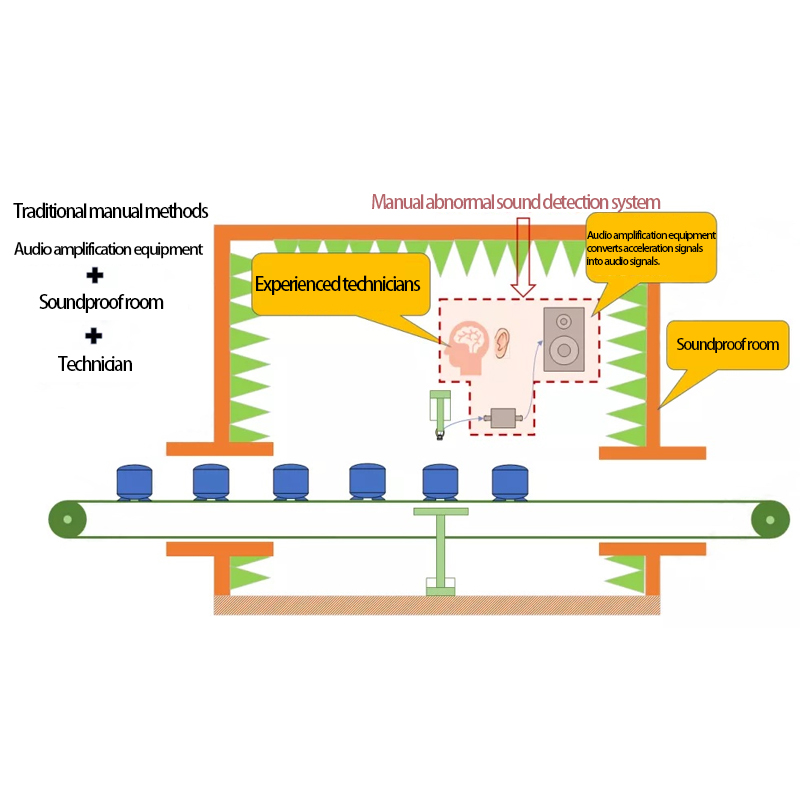

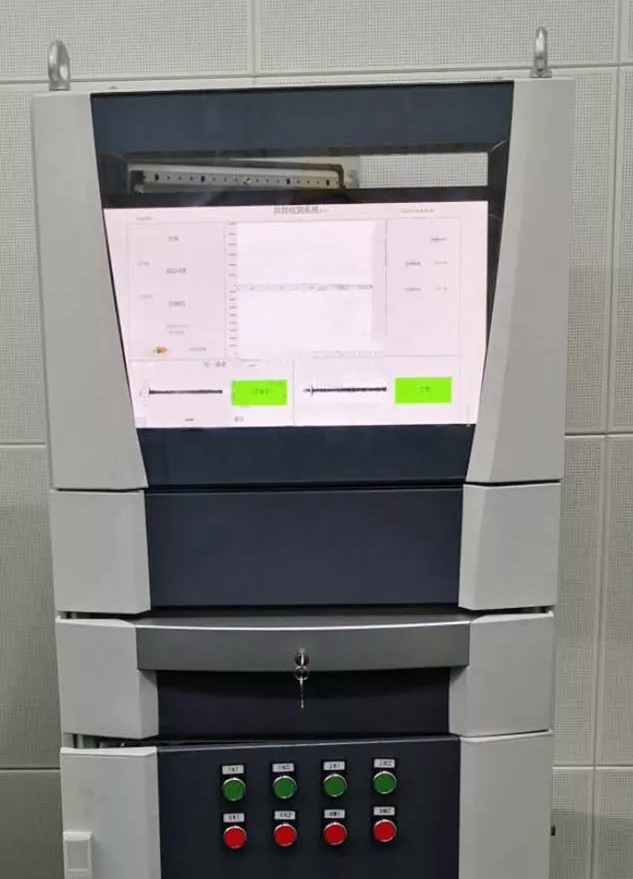

Compared with manual methods, AI-based abnormal sound detection no longer requires soundproof rooms or professional technicians. The system is composed of two parts: hardware and software.

Acceleration Sensor: Converts the vibration acceleration of the compressor shell into an electrical signal and outputs it.

Data Acquisition Card: Converts the electrical signal output by the acceleration sensor into a digital signal that can be stored and analyzed by a computer, and then outputs the digital signal.

Computer: Stores and analyzes the digital signals obtained from the data acquisition card.

Measurement Auxiliary Device: Supplies power to the compressor, attaches the acceleration sensor tightly to the compressor shell, and sends signals to the abnormal sound detection system to start and stop data collection (or detection).

· Software

Sample Collection Program: Labels, records, and stores signal samples, performs data cleaning, and establishes a dataset.

Machine Learning Program: Completes the training of the abnormal sound detection model and tests/verifies the accuracy of the model's judgments.

Abnormal Sound Detection Program: Applies the abnormal sound detection model to conduct online abnormal sound detection.

Due to the large daily output of the compressor production line, to facilitate the query and retrieval of records, it is necessary to upload detection results, data information, record files, and other data together with compressor identifiers to the database. Additional auxiliary functions need to be added according to specific requirements, such as:

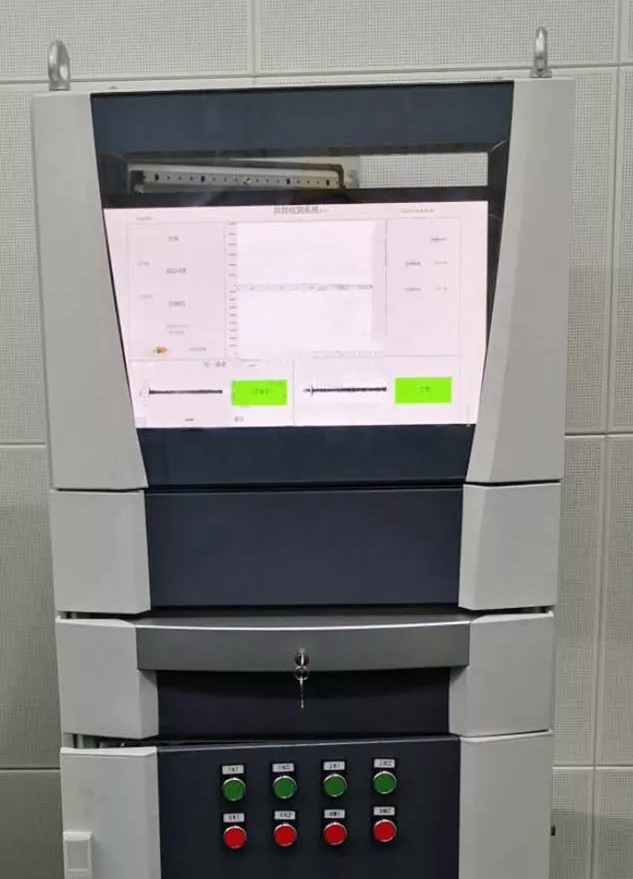

Control Methods: A three-fold solution including fully automatic control, manual control, and quick-button control.

Display Content: The detection software is required to display real-time information such as time-domain signals, 1/3 octave spectra, acceleration, and detection quantity statistics.

Fault Alarm: When a defective product is detected, an alarm is triggered in a timely manner to facilitate offline handling or marking of the product.

Database Connection: Upload detection results and related record files to the database for querying and locating defective products.