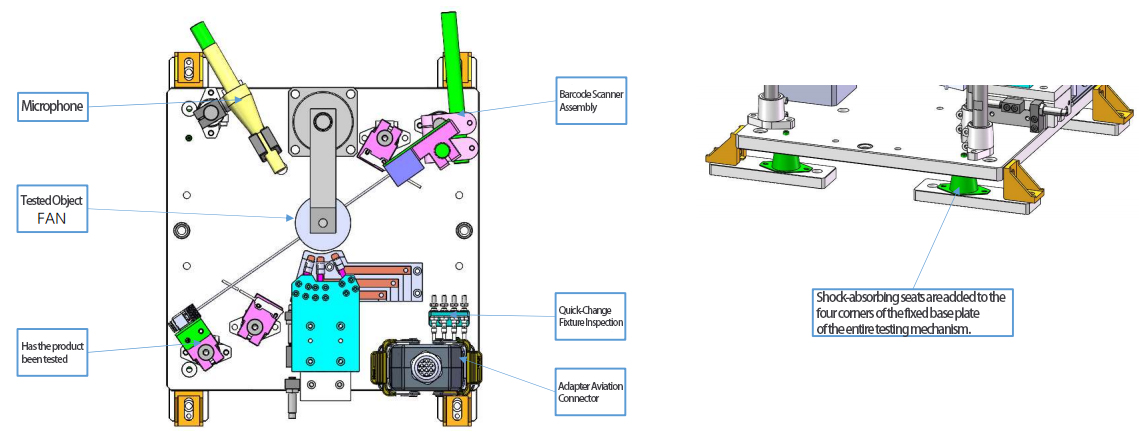

This equipment is used for fan noise testing. It adopts a single-station configuration with manual loading and unloading for testing. The basic information is as follows:

This solution is planned based on the following materials provided by the customer. If there is any change in the input, the solution will be adjusted accordingly.

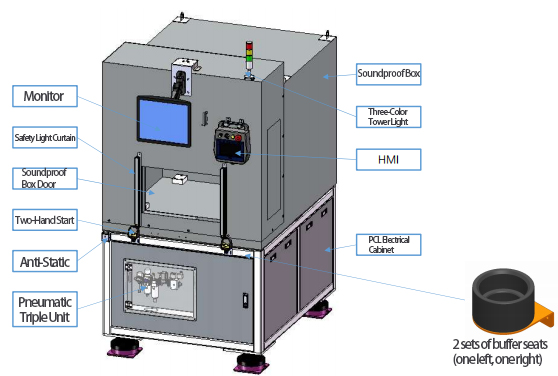

·An industrial industrial control computer (IPC) is configured, equipped with a mouse, a keyboard, and a monitor.

·An operational touchscreen is configured.

·A pneumatic (pneumatic triplet) is configured.

·A configurable barcode scanner and a three-color tower light are configured.

·A safety light curtain is configured.

·Dual-hand pneumatic buttons are configured.

·An anti-static controller is configured.

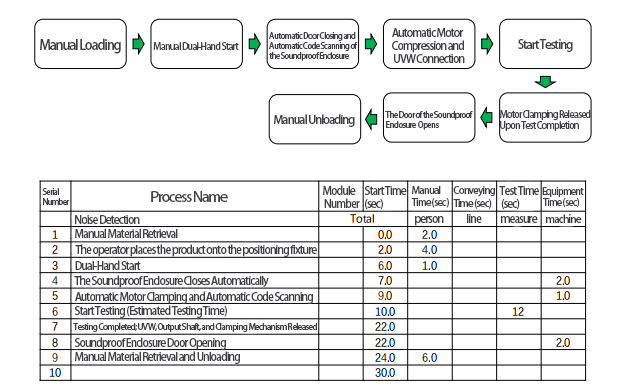

Material Conduction

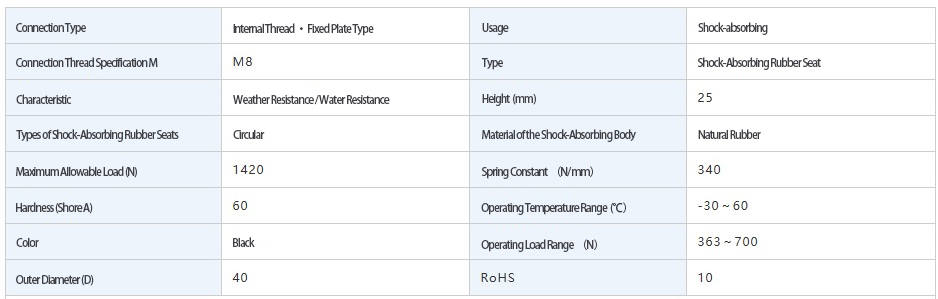

Natural rubber is an incompressible material with a Poisson's ratio close to 0.5. There is a time lag between stress and strain. Therefore, rubber is effective as a nonlinear shock-absorbing material.

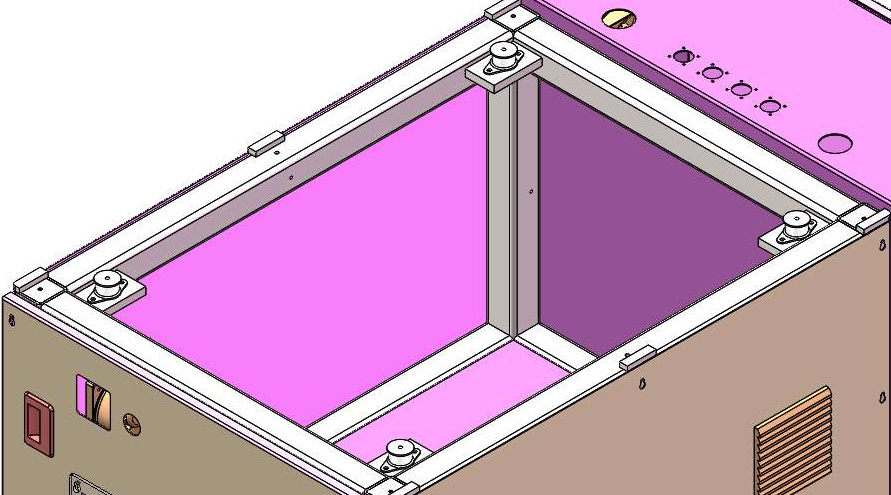

Shock-absorbing seats are installed on the workbench plate to reduce the transmission of ground vibrations to the MISUMIBGONP40250.

Top View

1.Equipped with a safety light curtain.

2.Capable of automatically adjusting rotational speed, with an error of less than 1%.

3.All models are accompanied by tooling, and the tooling meets quick-change requirements.

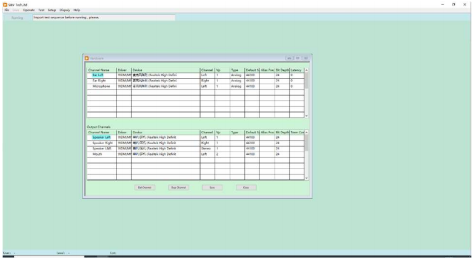

4.Built-in recording function: the effective recording duration per rotation shall be at least 5 seconds; recording storage shall be classified by date and model. Even for different models on the same date, separate classification shall be implemented.

5.The equipment's barcode scanner shall have a storage function, and data shall be stored corresponding to the model and date.

6.The equipment shall reserve an MES (Manufacturing Execution System) docking port.

7.The control power supply shall meet the requirement of 24V adjustable voltage.

8.For items not mentioned herein, refer to our company's noise-related equipment.

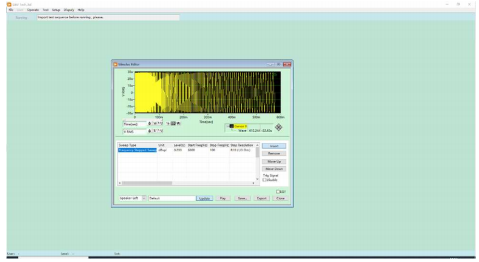

·Single-point waveform activation

·Continuous scanning waveform

·External waveform import

·User-defined expansion

·Test parameter configuration

·Hardware interface customization

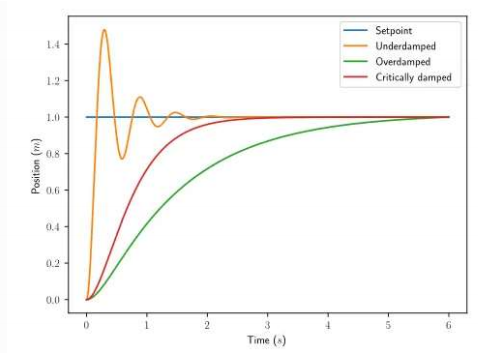

PID (Proportional-Integral-Derivative) control is a classic automatic control algorithm. It achieves precise regulation of the controlled object by combining the effects of three links: proportional, integral, and derivative. Its core idea is to dynamically adjust the control quantity based on the system's current error, error accumulation, and error change trend, so that the system output is stabilized at the target value (set value).

Contact: Mr. He

Phone: 13554924211

Tel: 13554924211

Email: sales@hzbaa.com

Add: 1st Floor, No. 99-15 Dayang Road, Rentian Community, Fuhai Street, Bao'an District, Shenzhen City

We chat